Concealed Door Hardware Accessories Hydraulic Floor Springs

Ground springs are mainly composed of springs, bearings, connectors and so on. Its working principle is to provide resistance through the hydraulic device, so that the door can be closed automatically after opening, and it has the function of slow opening and closing to ensure that the door closes smoothly and quietly to avoid damage or injury.

Ground spring doors are widely used in modern buildings, especially suitable for the entrances of shopping malls, banks, hotels and other high-grade places, as well as the main entrances of office buildings and exhibition halls. Due to its hidden installation inside the ground, the door looks neat and beautiful when it is closed. Our floor springs can support up to 200kg, contact us now to select the most suitable door and window accessories for your project!

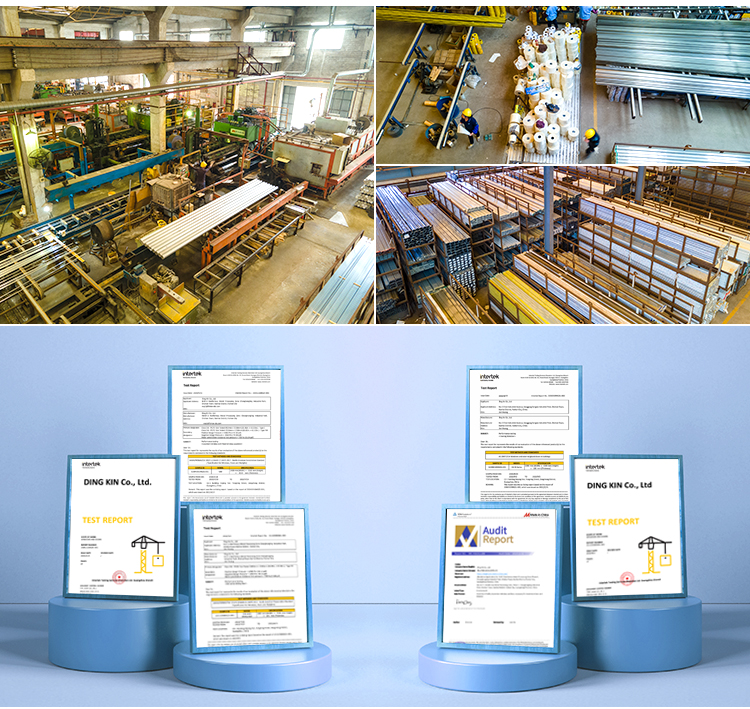

Production Process

YA JI Co., Ltd. offers aluminum building hardware floor springs in a variety of colors. These door closers are made of durable aluminum alloy and are perfect for glass doors, shower doors, office doors

| 1 | Raw material storage: The raw materials for hardware accessories usually include aluminum alloys, zinc alloys, and iron. These raw materials need to be stored in a dry and ventilated environment to prevent rust and corrosion. |

| 2 | Die casting or stamping: According to the design requirements of the product, the appropriate die casting or stamping process is selected. Aluminum alloys and zinc alloys are usually die-cast, while iron is usually stamped. In this process, the raw material is heated to a certain temperature and then molded into the desired shape through the mold. |

| 3 | CNC machining: For some hardware accessories that require high-precision processing, CNC machining may be required. CNC machining can achieve high-precision cutting, drilling, milling and other processing techniques to meet the design requirements of the product. |

| 4 | Surface treatment: In order to improve the corrosion resistance, aesthetics and service life of hardware accessories, surface treatment is usually required. Common surface treatment processes include electroplating, spraying, and anodic oxidation, etc. |

| 5 | Quality inspection: At all stages of the production process, quality inspection is required to ensure that the product meets the design requirements and quality standards. Quality inspection usually includes visual inspection, dimensional measurement, functional testing, etc. |

| 6 | Packaging: Finally, the qualified hardware accessories will be packaged for transportation and sales. |

Welcome to YA JI Co., Ltd.

Our hardware accessories are crafted with precision and care to meet the highest standards of quality. Each product undergoes a unique production process tailored to its specific requirements, ensuring durability and reliability.

Features:

● High-quality materials

● Precision manufacturing

● Durable and long-lasting

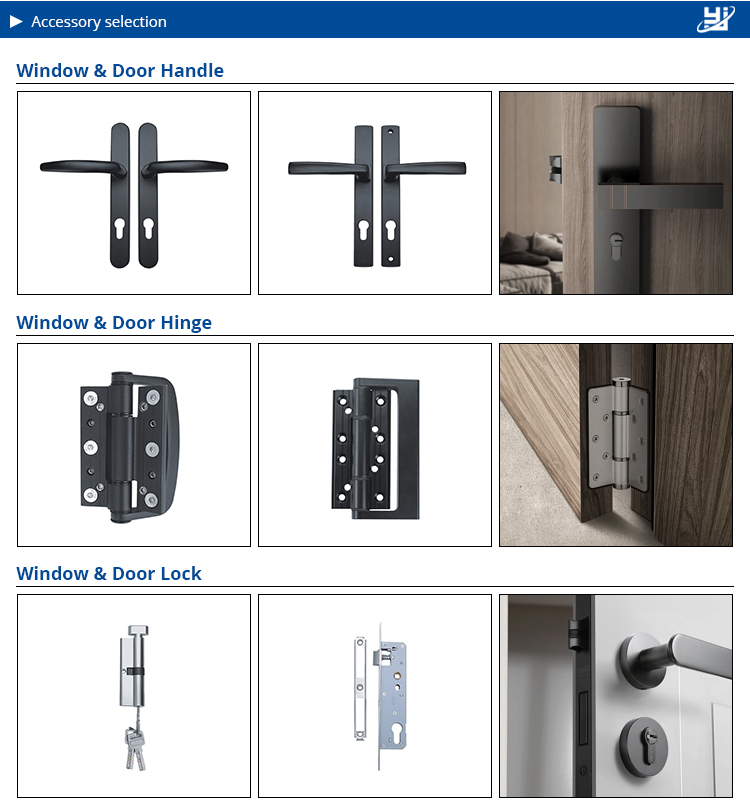

● Wide range of accessories available

Benefits:

● Enhanced performance

● Reliable functionality

● Easy installation

● Customizable options

At YA JI Co., Ltd., we understand the importance of quality hardware accessories for your projects. Trust us to provide you with top-notch products that exceed your expectations.