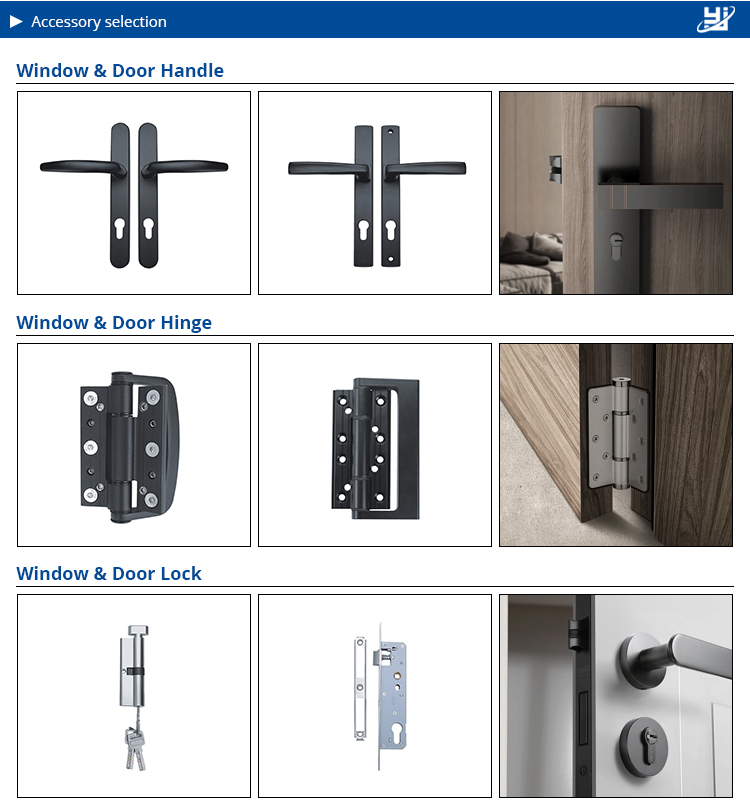

Window Hardware Accessories Aluminum Friction Fixed Hinges

Friction fixed hinges are mainly used to connect two solids and allow relative rotation between them. In door and window hardware accessories, friction hinges are usually used on casement doors or casement windows on the opposite side of the handle, playing the role of supporting the window sash.

In addition, the opening angle of friction hinge can reach 90 degrees, and it has the characteristics of good weather resistance, not occupying indoor space and convenient for users. Friction fixed hinge usually consists of slide rail, slider, bracket arm, long cantilever, short cantilever and oblique cantilever and other components. The slider is mounted on the slide rail, the long cantilever and short cantilever are hinged between the slide rail and the bracket arm respectively, and the oblique cantilever is hinged between the slider and the long cantilever, so as to realize the opening and fixing function of the window sash. Contact us today to learn more about how our aluminum friction fixing hinges can improve your space.

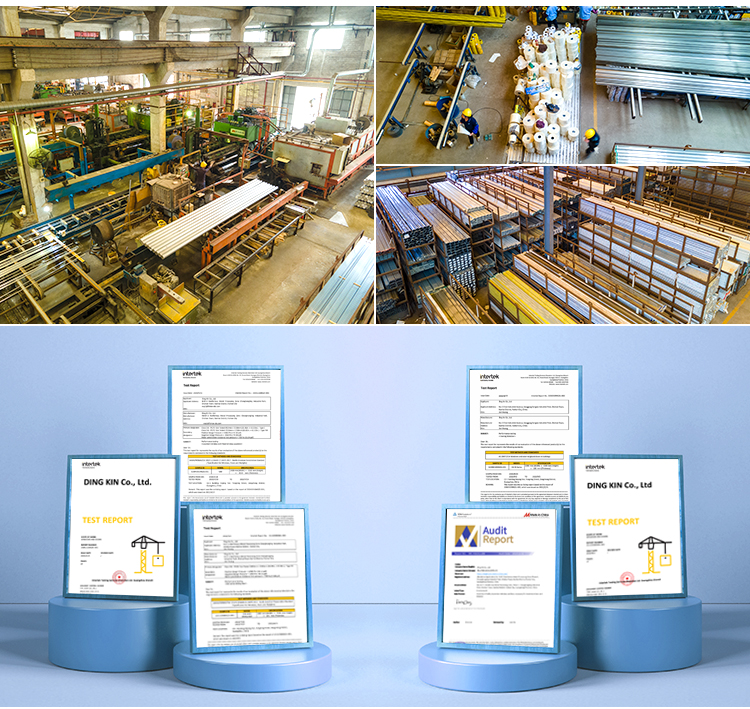

Production Process

YA JI Co., Ltd. offers Aluminum Building Hardware Friction Stop Hinges in various colors. These hinges are made of durable aluminum alloy and are ideal for use on casement doors, casement windows,

| 1 | Raw material storage: The raw materials for hardware accessories usually include aluminum alloys, zinc alloys, and iron. These raw materials need to be stored in a dry and ventilated environment to prevent rust and corrosion. |

| 2 | Die casting or stamping: According to the design requirements of the product, the appropriate die casting or stamping process is selected. Aluminum alloys and zinc alloys are usually die-cast, while iron is usually stamped. In this process, the raw material is heated to a certain temperature and then molded into the desired shape through the mold. |

| 3 | CNC machining: For some hardware accessories that require high-precision processing, CNC machining may be required. CNC machining can achieve high-precision cutting, drilling, milling and other processing techniques to meet the design requirements of the product. |

| 4 | Surface treatment: In order to improve the corrosion resistance, aesthetics and service life of hardware accessories, surface treatment is usually required. Common surface treatment processes include electroplating, spraying, and anodic oxidation, etc. |

| 5 | Quality inspection: At all stages of the production process, quality inspection is required to ensure that the product meets the design requirements and quality standards. Quality inspection usually includes visual inspection, dimensional measurement, functional testing, etc. |

| 6 | Packaging: Finally, the qualified hardware accessories will be packaged for transportation and sales. |

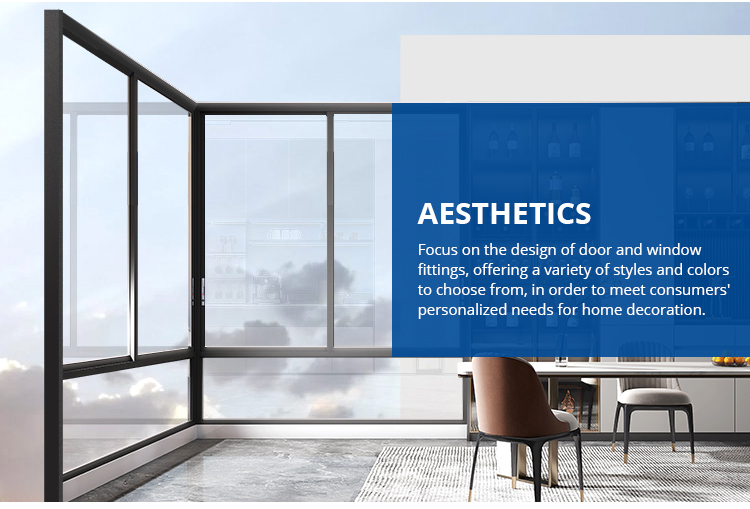

Welcome to YA JI Co., Ltd.

Our hardware accessories are crafted with precision and care to meet the highest standards of quality. Each product undergoes a unique production process tailored to its specific requirements, ensuring durability and reliability.

Features:

● High-quality materials

● Precision manufacturing

● Durable and long-lasting

● Wide range of accessories available

Benefits:

● Enhanced performance

● Reliable functionality

● Easy installation

● Customizable options

At YA JI Co., Ltd., we understand the importance of quality hardware accessories for your projects. Trust us to provide you with top-notch products that exceed your expectations.